CREDITS

HDA : FACADE DESIGNER

CLIENT : PHILARMONIE DE PARIS

ARCHITECT : ATELIERS JEAN NOUVEL

HDA TEAM : Hugh Dutton, Mitsu Edwards, Francesco Cingolani (Project Leader 1), Gaetan Kohler (Project Leader 2), Cathy Shortle (Project Leader 3), Maria Angela Corsi, Pierre Chassagne, Victor Ceaicovschi, Sébastien Perrault.

DATE : 2007-2015

The La Villette area, in the north-east of Paris, has been transformed over the past 20 years from a slaughterhouse district into a large park that includes public facilities for science, music and exhibitions. The latest addition to this cultural infrastructure is Jean Nouvel’s competition-winning design for the new Philharmonic concert hall.

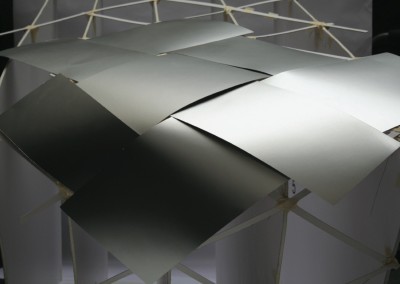

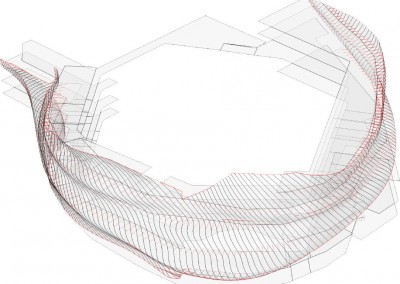

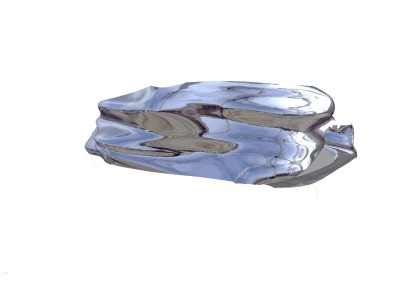

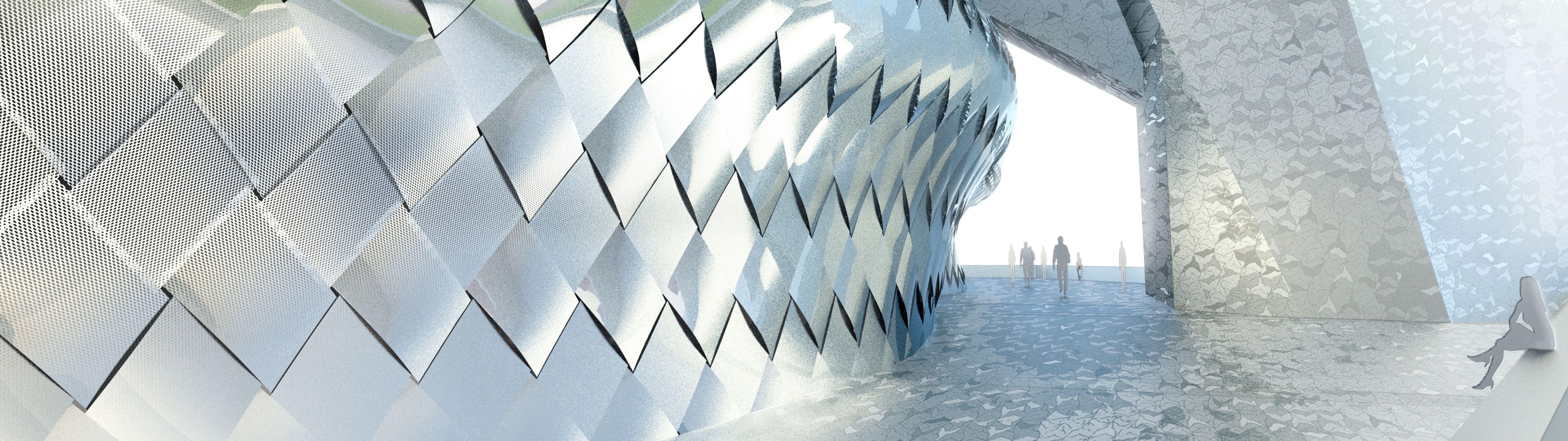

Nouvel’s design has an angular external carapace enclosing the soft fluid form of the foyer. This extremely complex shape is made up from two basic surface types which are used as both façade and cladding. Both are metallic, the carapace being in cast aluminium and the foyer – baptized the ‘Tourbillon’ – being in stainless steel.

HDA were appointed as consultants to assist the Nouvel team with the technical development of these cladding surfaces. This included system concepts, engineering analysis, technical documentation for tender, shop drawing review during the site phase, and model and prototype studies to demonstrate feasibility and tolerances of the cladding systems.

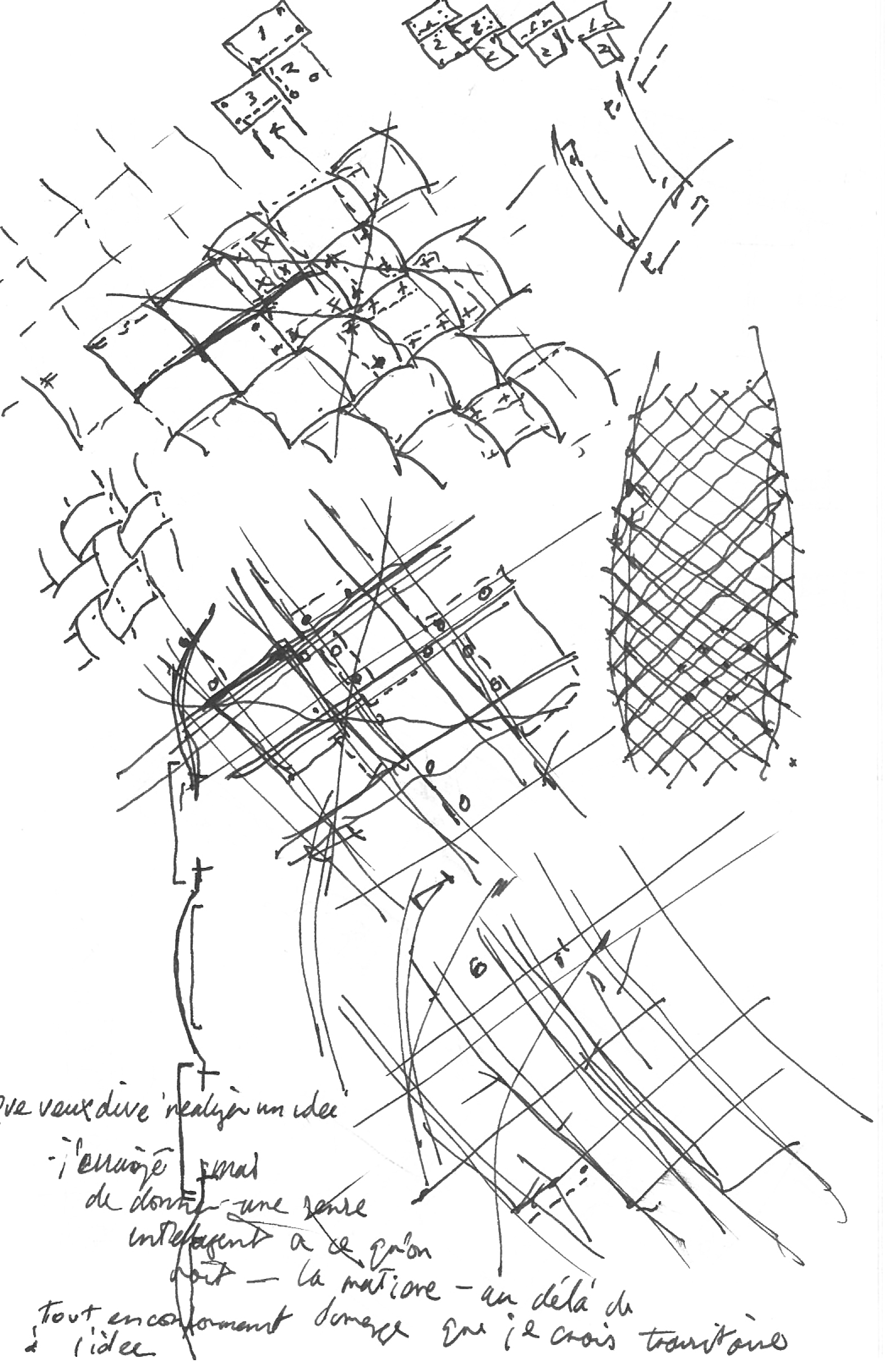

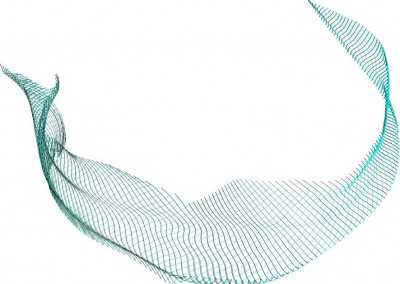

For the external carapace, the cladding system is based on a series of bird motifs arranged in complex interlocking tiles, evocative of Escher’s drawings. For the tourbillon, it was important for the cladding system to maintain surface fluidity. HDA proposed a system of individual panels that give the appearance of a woven texture and that allow the adaptation of developable curved panels onto the non-developable surface of Nouvel’s architectural form. The panels are fixed with adjustable brackets to steel plate sections whose profile is determined by planar cuts of the ‘tourbillon‘ form; these sinuous plates were named «banana beams». The cladding panels receive a mirror-finish to enhance the liquidity of the global form.